Buyo was set up to do something radical, said Buyo co-founder Hanh Do, by solving the problem of plastic waste at its root cause. While there are different solutions in the market, “our in-house technology can address both the plastic crisis and climate change. The material we use is waste.”

Buyo’s mission, then, is to solve the plastic pollution problem. “Plastic takes a long time to degrade,” she explained - “up to 500 years. It is the second most serious issue for the planet. It is a meaningful problem to address.”

Second Generation Bioplastics are Fully Biodegradable

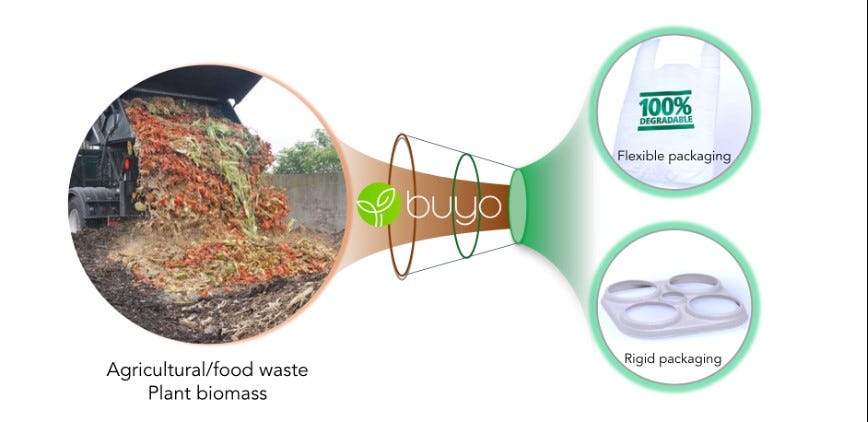

To solve the problem, Buyo focuses on producing alternative plastic materials to replace fossil fuel-based plastics. Buyo can create flexible or rigid plastics for packaging and other applications such as medical products, textiles or cosmetics. “Anything we currently use plastic for,” she said, “we can use alternatives.”

The most popular bioplastic solutions in the market currently are starch-based and PLA, Hanh observed. Although it is a nature-based bioplastic, PLA has limitations because it is only biodegradable in specific conditions with high temperatures. First-generation starch-based bioplastic products, on the other hand, use materials such as corn starch or cassava that are food for people. Moreover, it has limitations in properties such as tensile strength and barriers to moisture and heat.

Second generation bioplastics overcome this constraint, Hanh explained. They are fully biodegradable in the natural environment and offer comparable strength to existing plastics.

Buyo uses a biological process to produce second generation bioplastics. It takes bio-waste as a raw material and then uses micro-organisms and bio-fermentation to convert the waste into biopolymer. Buyo mixes several types of biopolymers together to create the properties they want.

Bio-waste such as agricultural or food waste is not something special, she noted. It is thrown away or used for low-value applications. “We have found a way to upcycle it, thanks to our technology.”

In the initial stage, Hanh said, Buyo is manufacturing bioplastic by itself. “We want to build our manufacturing capability, for product development and for new applications. We need to control manufacturing and quality. When we scale up the process, we can license the technology to other manufacturers.”

As it scales up and starts to license the technology, Hanh said, Buyo wants to minimise the modifications required in machinery, equipment and production processes at existing plastic manufacturers. “This is the purpose of the pilot. We will design production processes, machinery and equipment so they fit in with existing systems.”

Second Generation Alternative Plastics have a Competitive Advantage

While there are other players in the market who supply bioplastics, the biggest competitor to BUYO is regular plastic. The issue is how to educate and convince customers to switch when the cost of bioplastics or other green alternatives in general is higher than regular plastics. While the price for bioplastic is higher for now, it is expected to drop as volume scales up and will then likely match pricing for existing products.

PLA and starch-based plastics have been commercialised for many years, so they are also competitors. And there are competitors within the second-generation technology segment, though most manufacturers are in North America and Europe, and few are in Asia. “The market is big enough for us to join to supply new alternative materials,” she said, and “we can help shape the market. When there are other suppliers like us in the market, we can have a voice in supporting the shift from traditional plastics.”

Target Customers are Large Multinationals in Europe and North America

“We target corporates that have a strong green agenda and an ESG mandate and that care about sustainability,” she said. “If those who care about a circular supply chain offer us bio-waste, we can convert it into bioplastic applications for them.”

BUYO also believes that European and North American markets are pioneering markets for this green alternative. Some multinationals in Asia are also open to plastic alternatives.

Next round of fund raising and scaling up by 2024

Buyo completed a pre-seed round of funding in March 2023 and expects its next round of fund-raising to be next year.

While it is an early-stage company, sales are growing significantly and it is looking forward to the time when it covers costs.

Impact

Hanh’s reason for creating and building Buyo is both professional and personal. Her previous employer, in the textile and garment industry, was very environmentally conscious and imprinted its philosophy on her. “Whatever we did at that company, we placed people and planet first.” At a personal level, she has two children and wants to leave them a legacy that is good for the environment.

And she is confident of success. “This is great timing. Many governments are banning single use plastics. Alternatives are becoming mandatory. We have a strong team, with top scientists in this area. We have the right timing, the right people, and the right purpose.”